Accueil ' Forums ' Equipement ' Conversion du Bain Marie pour qu'il fonctionne à la vapeur basse pression

-

Conversion du Bain Marie pour qu'il fonctionne à la vapeur basse pression

Publié par mtr_distiller on octobre 18, 2021 à 7:20 pmIs it normally possible to convert an electric-fired jacketed baine marie mash tun or still to low pressure steam? If so, any special considerations?….Thanks for your feedback!

ville des vents répondu Il y a 3 années, 1 mois 6 Membres - 12 Réponses -

12 Réponses

-

it depends if the jacket has been designed for pressure. if it has then yes it is possible, use highest port in the jacket for steam input and lowest for condensate trap/return cap all other ports

-

Yes, We have a conversion kit for our own baine marie stills. First you must have inner pot and jacket wall thicknesses of at least 3 mm for 6 psi steam and at least 4mm for up to 15 PSI steam. Our kits consist of high pressure clamps, Teflon gaskets and end caps for your heating element ports as well as an appropriately sized Apollo ASME rated section VIII pressure relief valve for your steam jacket and the appropriately sized Apollo vacuum relief valve for your steam jacket. paul@distillery-equipment.com

-

If your electric was an oil jacket you will need to cleaned the living F out of it. The oil will be a total pain in the ass on all your steam traps and one way valves as well as get into your boiler.

-

Yes the oil must be removed from the stills jacket. So far, none of our 20 or so customers, who converted their baine maire stills to steam, have reported any issues.

-

Are you planning on running this off of a low pressure steam boiler or are you wanting to turn the Bain Marie into a self contained steam boiler/still

I converted my Bain Marie into self contained steam and it works great

-

Windy – I am exploring options for a future move. My first thought was to run it off of a low pressure steam boiler.

-

Paul, Are your standard BM units are capable of this conversion or do they need specified that way when ordering?

-

I purchased a used Bain Marie from a distillery in Tennessee. They had problems with their controller and burned the oil causing a crust of burnt oil on the inner jacket and not allowing proper heat exchange. I filled and circulated hot water PBW, then Dawn dishwashing soap and finally citric acid. After about a week of this regiment (and a five gallon bucket of PBW) the inner jacket was squeaky clean

-

Part of my living is building large hydronic heating systems (boilers).

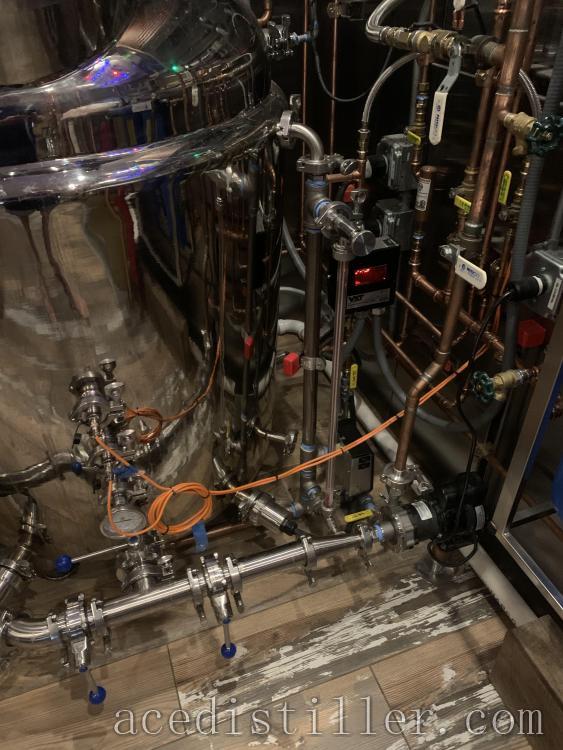

my Bain Marie is 110 gallons working. I didn’t want to go back with oil for a few reasons, one of them was the slow response time. I installed 4- 6kw stainless elements. I then made the jacket the same way I would build a steam boiler. I installed a low water cutoff, a auto feed, a high pressure cutoff, a emergency blow off, site glass, pressure gauges, low pressure relief valve, vacuum relief valve and a steam auto vent.

When I am distilling (on the grain) I have my mixer set at 30. With the heat being transferred like this it actually never builds up any pressure until the mash is up to 210f but at that point I am pretty much done with the run. The pressure at this point is only about 2 psi

-

My Bain Marie is actually a Affordable Distillery boiler 😀

Paul / Jonathan at Affordable Distillery built the 8” side column for me. I talked to Paul a bunch before I did this conversion and as always he was very helpful. Always a great guy to work with. Thanks

Connectez-vous pour répondre.