-

Why Isn’t My Soxhlet Siphoning Properly?

Posted by needmorstuff on May 6, 2020 at 7:57 pmI had a 1.5l soxhlet made to experiment with, for some reason the liquid level gets right up to the vapour inlet which is above the syphon tube but it doesn’t auto-syphen. Have i got the design wrong?

Teh down the tube shot is showing the liquid level all the way up to the vapour inlet tube.

needmorstuff replied 4 years, 7 months ago 3 Members · 11 Replies

needmorstuff replied 4 years, 7 months ago 3 Members · 11 Replies -

11 Replies

-

what is strange is that when I tested it with just water it siphoned just fine

now with 2 x hop bags full of fruit on top of cotton pads it doesn’t syphon unless I move the “u” bend down 60mm from the top of the liquid level, the total height of the chamber being 320mm. Even then I wouldn’t call it a syphon.. more a constant trickle.

-

I think maybe I need a disc of metal on top of the siphon tube for the cotton filter pad to rest on.. I think the cotton pad and bags of fruit are stopping an effective siphon action by slowing the flow rate of the draining action.

Will test tomorrow.

-

You probably have it there. The soxhlet works by vacuum created by the fluid moving back into the boiler. The fluid level has to be above the top of the U in the drain. If you don’t have enough fluid to go over the top of the U then it won’t work. Gravity pulls the fluid down creating a vacuum further back. If the fluid can’t flow freely then it won’t drain properly.

-

Hopefully….

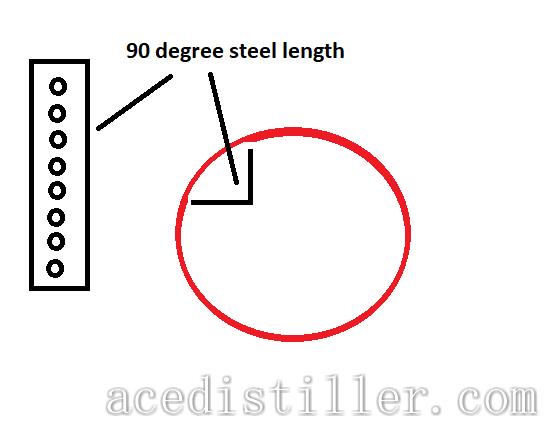

I don’t have a “thimble” either, so the hop bag of fruit can essentially create a “plug” – I may need to add something to run vertically the length of the chamber to create a path to drain from and further stop the plug.. maybe a piece of 90 degree steel with holes drilled the length

-

I have replicated this in a more controlled environment (kitchen)

with a soggy bag of fruit over the drain hole it doesn’t syphon

with the drain hole protected by a drilled copper disc then a soggy bag of fruit over it syphons very very slowly.

with the drain hole protected by a drilled copper disc and a relief channel running the length of the chamber atop the disc then a soggy bag of fruit over it syphons perfectly fine.

Protect the drainage path is the answer.. easily solvable by an L shaped piece of steel drilled full of holes running the length of the chamber in my case.

-

You could probably have these guys create something custom for you. Kinda like a gin basket so the sides always have a path for the fluid. The top of the U of the drain line should be right at the top of /slightly above where your botanicals/fruit/whatever is. The idea of the soxhlet is to soak the materials in the solvent. I’m building one out of a StillDragon gin basket right now. It’s easy to do. I need to work on the drain line. You can see how to change the vapor flow, drainage & condenser setup in the second photo. Larry was awesome and helped out with drawings of how to setup the hardlines for drainage instead of the silicon tubing in the image.

https://www.utahbiodieselsupply.com/brewingfilters.php

-

ooh, great idea. I like the hop spider thinking. I will see what I can find in the UK.

I did think of using my 4″ gin basket but the extra bits i needed to buy would cost more than a custom built one with a 1.5 litre capacity. It set me back like $130, whereas obtaining SS Spool parts for me is expensive.

what are you extracting? that seems very small for your kettle..

-

perfect for my small extractor.. 29x7cm

-

We’ve built some really big soxhlets from stainless. If anyone needs one just let me know paul@distillery-equipment.com

Thanks.

-

would you care to share your experience in this field? or offer any advice.

-

creating the path for the liquid to drain was the key, it works like a charm now. I have ordered a hop spider for it which will be a more elegant solution.

Log in to reply.