-

Verifying the Functionality of Heating Elements

Posted by derekduf on November 5, 2019 at 7:22 pmAnyone have any recommendations on how to check/verify heating elements are working to their full potential? I know its kind of a loaded question but running out of ideas. We have 3x 7kw heating elements in a 100 gallon still. Our heat up times are ridiculously long. In our latest test batch, with putting about 15 gallons of water in the jacket of the pot, even after 4-5 hours the water in the jacket never got hotter than about 180ish. The elements are hooked up to a control panel. I have verified with the manufacturer that everything is hooked up correctly and is supplying enough power. My electricians have come back and verified the elements are wired correctly. Obviously I know the elements are heating, but is there some simple method to verify they are all working to their full potential and not having a loss of power somewhere along the way?

southernhighlander replied 5 years, 1 month ago 6 Members · 24 Replies -

24 Replies

-

What is the amp draw per element and what is your phase and voltage? What phase and voltage are the elements made for?

-

As noted above, we are short on information. You need to be able to dynamically read current and verify that your controller is also working correctly, as in energizing the elements at the correct time and keeping them online until setpoint is reached etc.This requires electrical skills and test equipment or having your electrician present when you are shaking the system down, and then knowing what to look for. 2100 Watts at 240V is about 90 Amps worth of power which is a fair amount. I would have to doubt that you are energizing the full array based on your report if it is sized correctly for the load. This kind of diagnosis involves working with and around live terminals, and should not be gone into lightly.

-

We have 3-phase 208v power. Each of the three wires to each element shows 5.5 amps. I’m waiting to hear back on specific specs the elements should be getting, I was originally told the elements required 60 amps.

-

If the elements are 7kW and they are 208 3 phase elements, they should draw 19.44 Amps each, under a full load. The elements should be stamped with the phase and voltage on the terminal end. .

-

Derek,

Were the controller and elements made in the US or China? Also please follow Starcat’s advice and have an electrician do all of the metering.

-

The elements are from China. The controller was built locally.

-

5 amp draw against 20 amps expected sound like they might be 480v three phase elements. 1/4 the current draw would be expected at half the voltage.

Not an electrician, just something to check.

-

Wired line to neutral for 3 phase for each heating element, the current draw is 11.8A .

-

are the elements wired in Delta or Y? If they are supposed to be delta, and wired in Y this could explain the low draw. if this is the issue, it could be wired this way in your panel or directly at the elements themselves

-

Do the elements have the phase and or voltage stamped on them? Do you have pics of the inside of the controller and of the elements?

-

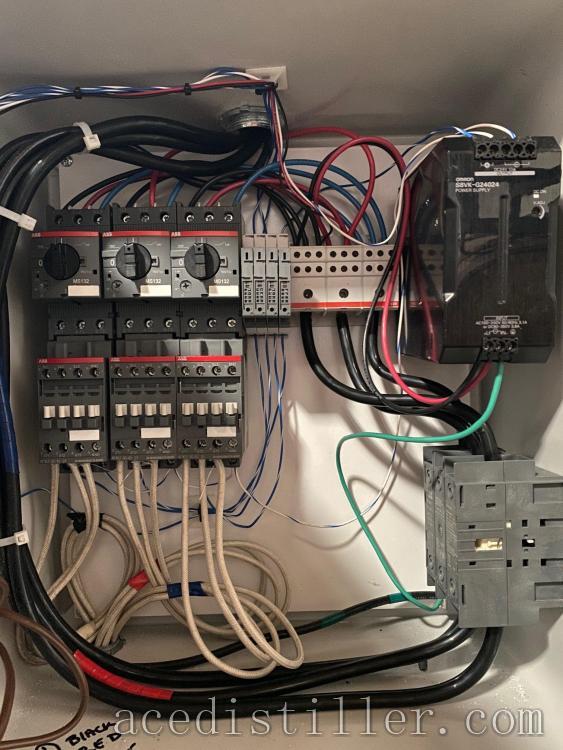

The elements are 230v 3 phase 60hz. Attached is a photo of the wiring. The white lines on the bottom left go to the elements.

-

If the PID is a more expensive one, the problem could be with your PID. Some of the more expensive PIDs have proportional control and they can set up to reduce the proportional output to the elements when you get close to your set point temp and that may be the default setting for the controler out of the box. If the elements were metered when the temp was close to the set point, you may have gotten a lower amp reading because the PID had throttled the elements back. If the PID is throttling the output back when the set point temp is approached, then this also could cause a very long heat up time Try setting your setpoint temp 20 degrees F higher than your target temp and see how long it takes to reach the target temp.

Also have your electrician meter the elements half way to the target temp and have him check the resistance in the elements as well and ask him if the PID has proportional control and what the settings are for the PID.

My calcs show that your 230v 3 phase elements fed 208 3 phase power will draw 9.17 amps per leg and put out 1,908 watts per leg giving a total wattage of 5,724 per element. With all elements running correctly and producing a full 5,724 watts each, your heat up time for 100 gallons of grain in mash should be around 2 hrs and 15 minutes.

Also look at the pic below and let me know which way your elements are wired: star delta or delta?

-

ABB MS132 is just a straight manual motor start contactor – there isn’t any kind of SSR/Power controller that can vary proportionally that I see, the AF16z below is it a simple on/off providing remote control.

-

Here is what I see. I see 3 motor starters with contactors and next to them I see 4 devices that could be SSRs and I see a 24 volt power supply (the big black box). I see 24v control wiring coming from something in the door, which is probably a PID (that’s usually where they are placed). If those devices mentioned above are SSRs then this certainly could have a proportional control PID. If those devices are not variable SSRS and are instead fuses then this could not be a PID with proportional control. However on off control PIDs can be set to cycle on and off just before the set point is reached and this can also lead to long heat up times, so he should still try running with a set point temp 20F higher.

We use both electromechanical relays and solid state relays in our panels. Meaning each element has both a electromechanical relay and a solid state relay. A control panel that has SSRS only, is a hazard.

Anyway, my biggest question is why did they use motor starters instead of regular electromechanical relays. The motor starter will work but why use them? This is not what they are for. Also most likely the motor starter contactors have a more limited number of switches before the contacts need to be replaced. This is not a design I would use at all. It makes me wonder if the electricians have ever built a panel to control immersion heaters before.

The problem may not be the PID and is most likely the elements or the way that they are wired. I’m just brain storming and looking at all possible possibilities.

At least my amp draw and wattage calcs give the electricians a base line to go by.

-

I made an edit to my post, was looking on my phone and didn’t see the relays below it clearly.

It would be a simple on/off system if it was controlled.

-

I edited my last post as well so you might want to look at it again.

-

After more thought the 4 devices cannot be SSRs because they do not have room for external heat sinks.

-

This was a post that was repeated by accident so I deleted it.

-

They are wired in delta connection. My electrician is recommending bypassing the control panel and wiring the elements directly to do a test heating cycle and see if they work better to determine if an issue lies within the control panel.

-

The 4 small grey parts to the right of the overload devices are fast blow fuses (glass). I suspect that … they are wired to lights on panel door front (from a phase of each of the 24V coil contactors). On panel door there must be a switch to bring these contactors in.

-

In the heat element connection above from southernhighlander, …… Very nice picture.

But the first connection, STAR-DELTA is missing its neutral connection.

-

There is no neutral connection. Our electrical systems are different than yours. You have a single wire 220v that goes to neutral for your common household power, right? Our 220 is two 110 legs . Our common household power is 110v to neutral. Also you are 50HZ and we are 60Hz. Anyway the pics are correct for the USA.

-

That’s a great idea.

Does the control panel have a PID in the door? Doing a resistance test on the elements would be a good idea as well.

If it turns out that you need a control panel and elements, email me paul@distillery-equipment.com. Our panels and heating systems are built in house and we have them in over 130 distilleries. If one of our elements burns out, you can buy a replacement at your local hardware store for $30.00

Are your elements in the wash or are they in the jacket of a baine marie still? If the elements are in the wash, simple proportional control with a rheostat and variable SSRs work best. Set point temp control is not the best for stills with the elements in the wash.

Set point temp control works best with baine maries stills, where the elements are in the jacket with your temperature probe in the jacket as well.

Log in to reply.