-

Mix – Thickness/Temp

I do a fairly standard whiskey mash. Right now, I am using about 51% blue corn, 16% Distillers malt, and 33 percent rye. I grind everything into a flour.

This past weekend, I had a stuck fermentation which never really started. This happens to me fairly randomly. Most of the time, I have no issue whatsover and the ferment takes off in about 12 hours. I use a standard distillers yeast. But every once in a while they don’t start. This leads me to a few questions which might explain what is happenning. It seems when I get stuck it may be because the mash it too thick or too hot.

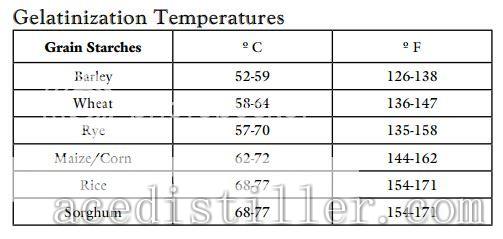

What is the optimal temperature of water to mash at? Should I mash the rye and corn at a hotter temp and then put the barley in later?

Typically I put it all in at once with close to boiling water and have no problem.

What is the optimal ratio for water to grain?

I’ve been doing somewhere in the range of 6 gallons to 12LBs of grain. I think this weekend, the mash was more in the range of 14-15 lbs. It seemed too thick.

Also, what temperature do you do your ferments at? I’ve been getting good results starting at 90 and letting it stay at around 75 after that. I typically let the ferment go 7 days but it is typically done by day 5.

Thoughts?

Log in to reply.