-

Is it Crazy or Possible? Three Bubble Plates Arranged Side by Side

Posted by needmorstuff on October 6, 2021 at 11:28 amI want to make vodka, I only have 3.2m of ceiling height

I have already bought and paid for a 4 x bubble plate 300l still from dye with 22kw.

Now I know 12 plates isn’t ideal from a throughput point but I am thinking 12 can make vodka. With that in mind what are the thoughts on this? or indeed thoughts anyone has on other options. all considered at this stage, I’d prefer to not buy another full still though as my space is limited.

I also have a 100l still dragon kettle at my disposal.

Volume wouldn’t be huge for the vodka, and the 100l could work for capacity.

alex_sor replied 3 years, 2 months ago 10 Members · 24 Replies

alex_sor replied 3 years, 2 months ago 10 Members · 24 Replies -

24 Replies

-

My personal opinion is to use pumped reflux across each column, and not a shared drain system with separate reflux condensers.

I think that the shared reflux drain adds considerable inefficiency to the mix, and you are already approaching this from behind, so you need to exploit all the tricks.

From a cost perspective, eliminating two of the condensers is a big cost savings, which will help offset the pump cost.

-

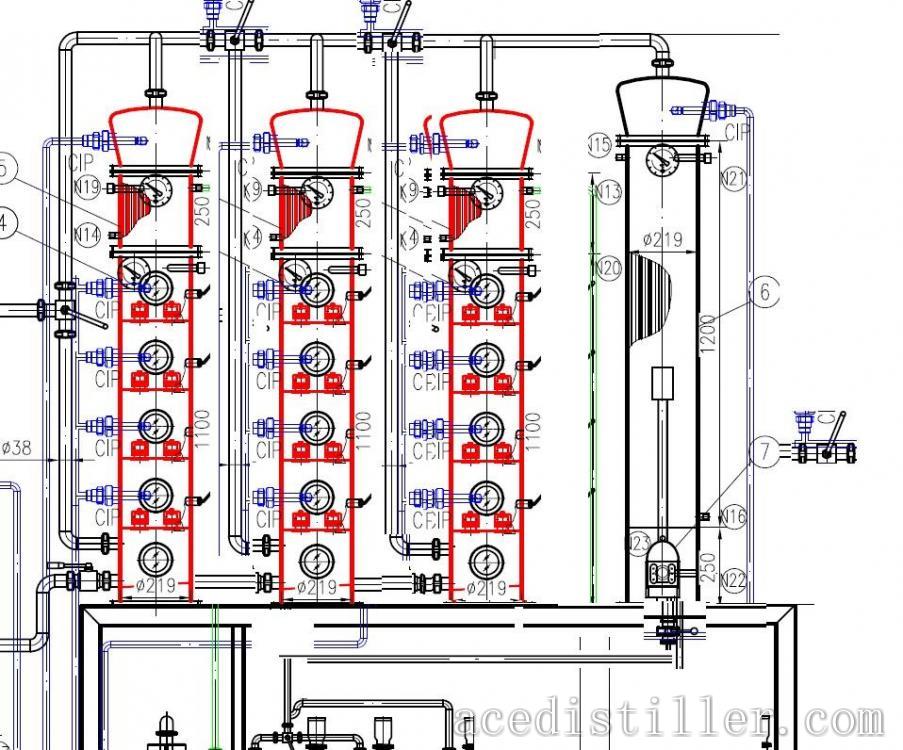

my head’s spinning now.. not sure where thge pumps going or pumping what to where! seems complicated, and I’m not usually one to recommend complication in any apsect of life. Is this what you had in mind?

-

Can’t really make it out on the drawing. But the liquid from each column bottom pumped to the top of the proceeding column (bottom of 3rd to the top of the 2nd, bottom of the 2nd to the top of the 1st). Bottom of the 1st would return to the kettle. So 2 pump systems. 1 single reflux condenser at the top of the 3rd.

Paul can weigh in on this approach as well.

-

yes drawing is sloppy, that’s what I had guessed though. and noted on the pumping direction. I doubt dye will have the knowledge to build this tbh.. seems very turnkey. I wonder who is using one of these who I might reach out to for advice.

Failing that, or some other design – I could strip the sugar wash in pot still mode on my 100l kettle. Then for the spirit run put a 1.5m 4″ SPP packed coulmn on my 100l. It has 6kw, but i could swap out the elements for higher capacity ones if required.

-

I think 12 plates for vodka is an exercise in frustration, but if you are going to use pumps between columns you can set them on the floor for maybe almost double the number of plates. You’ll need one extra pump though to drain to the kettle.

-

The pumped system is far more common than the individual drains in my experience. As Silk has suggested, for conversions between the two systems Paul ( @Southernhighlander) is definitely the “goto” guy.

-

The pump setup, as silk describes it will work fine, However, I would lower the columns to the floor, add a 3rd pump and have 20 total plates. We have dealt with similar height restrictions in this way with great results.

-

They key here, as other have said, is that you’re trying to make something work that isn’t ideal. You’re going to put a ton of work and money into something that may not produce great results and will require a fair amount of daily setup/breakdown and babysitting to ensure best results. 12 plates can make vodka, but depending on your desired flavor profile it may not work very well. Unless you need a produce a TON of product StillDragon has a small continuous system. I think it might just fit your height requirements. It will be way more efficient and easier to run than the system you are envisioning. I know you already have put money into a system but you should price it out. Keep what you have for whiskey/rum/brandy and buy this system for vodkas.

https://stilldragon.com/blog/advantages-of-continuous-distillation/

Images:

-

I love this forum!

floor standing plates – genius.

totally agree with the tear down etc.. will checkout the continuous column as I won’t be making a ton of product.

cheers everyone

-

if you are doing a stripping run first, you could always explore a section of packed column and get more theoretical plates per foot of height to maximize your efficiency with the low ceiling height requirements. Ceramic raschig rings are commonly used in industrial applications to achieve a good HETP (height equivalent to theoretical plate).

-

needmorstuff,

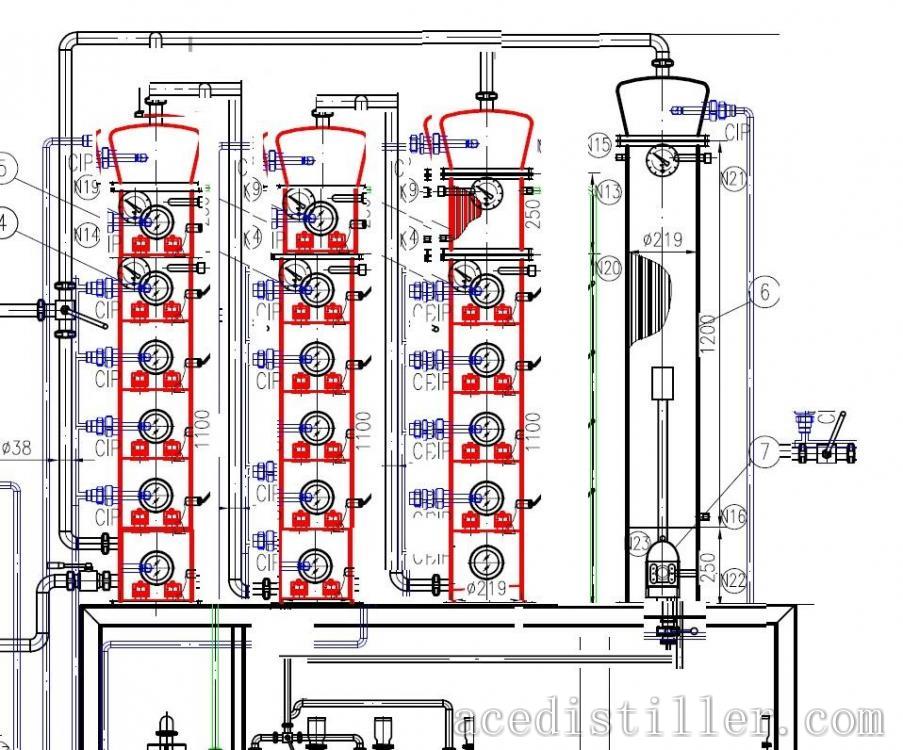

Below is a picture of one of the many stills that we have built for customers with height restrictions. This 300 gallon Ultra Pro Vodka Still with Gin Basket is less than 9 ft tall. The still is easy to operate and runs as smoothly as any 20 plate still. You can run any individual plate column and any number of individual plates in the system or bypass the bubble plate columns altogether with a turn of a handle. The dephlegmator and final condenser coolant flow is semi automated using a single thermostatic valve (not shown). The gin basket can be bypassed with the turn of a handle. Unlike certain continuous bubble plate columns, which must be torn down to remove plates to disengage them and then reassembled, no tearing down is necessary to reconfigure our Pro Series and Signature Series stills. Just the turn of the handle is all that’s needed. Our fastest stills put out 75 gallons of white dog per hour and cost less than any new continuous column still that we have seen with the same output. This still can also be used as a mash tun if needed. If you would like a quote for a still that would be designed specifically to fit your needs email paul@distillery-equipment.com and we will set up a phone conference.

-

You should just buy from Paul he knows what he’s designing. Will always help you. Helped you when he didn’t even have a sale out of you!

don’t worry, if you don’t buy from Paul he’ll help you fix whatever defects your still comes with because it wasn’t designed by someone who knows what they’re doing!

-

If you’re only running 100L and want to go really cheap you could just put a 2″ or 3″ packed column on top of the 100L boiler. It will be very slow, but you can just run it whenever you’re running the big still. That’s essentially what I do with 4″ column and a bit more ceiling height.

-

looks amazing, I already bought a still though – so looking for somethin to retro fit to that (which is sounding very silly now) or something to mount atop my 100l kettle.

my problem was i had to buy the still before I knew the location and only recently decided to add vodka to my product portfolio.

-

So I’m kinda thinking

use my 100l kettle (900mm) (already have this)

4″ Bubble section with thermowell (156mm) https://www.stilldragon.eu/en/dash-columns/287-bubble-section-with-thermowell-for-4-inch-dash-sgk.html

4″ column filled with SPP (1500mm – could maybe stretch to 1700mm but wouldn’t know until I am in situ)

4″ |Super Dephleg (300m) https://www.stilldragon.eu/en/condensers/30-4-inch-super-dephlegmator.html

4″ to 3″ reducer – into a 180 bend (adds 250mm) then into a 3″ PC (already have this)

Power, 2 x 3kw elements (one under control) – I can increase power as I will be buying new elements.

-

Before you make a final decision, you should check out our products and do some comparisons in price etc. https://shop.distillery-equipment.com/ If you want you could email me paul@distillery-equipment.com and I will put a package together for you. We have packed column sections in stock as well as everything else that you need + we actually have complete American made electric heating systems with controllers. We also have agitators, which unlike the ones on Chinese stills, have American made UL listed explosion proof agitator motors. We also have ASME rated American made safety valves. Typically the Chinese use non ASME rated safety devices that are not up to code in many situations. The Chinese typically use CE listed motors that say EX on them. CE is not up to code in the US, so many times the Chinese CE listed motors will not pass electrical and or safety inspections. Also if you will be running Vodka in an electric still, a jacketed pot for running 50% low wines is safer. We have 100 liter jacketed still pots that are inexpensive compared to our competitors and we sell American made heating systems with them.

-

I would have to agree with Paul 1000% on ASME pressure reliefs and the correct code on electrical components, but then i just noticed you were referencing stilldragon europe and all you measurements are in metric, so possibly USA codes and regulations do not apply?

either way make sure what ever you do you do it safely and in accordance with your local codes and regulations. with a configuration like you explained in your parts list i would at least make sure you have a pressure relief on your boiler with a packed column because unlike a bubbler plate with a sight glass you will not be able to tell if it is clogged. a clogged column will then make your bottom boiler build pressure until it relieves somewhere, either from a valve or by making its own path, such as exploding or rupturing the boiler vessel.

It is not a likely it will clog but do you want to bet your life on it?

-

I’m in the UK

To be clear my dye still is bought and paid for.

My kettle does have a European PRV.

I would be creating low wines on my 300l jacketed still.

Paul – I’ll shoot you on a mail.

-

Sounds like you are pretty set, and are looking for how to get this rig to work best.

Really though, worst case, you are talking about 3 distillations. You got strip on one side, spirit on the other. Not the most efficient in time, yield, or energy, but you could play around with double distilling on the 12 plate, or even double distilling on the pot first.

-

i’ve a 300l with 4 plates, could strip through that then onto the 100l column

-

I’m sorry, I didn’t realize that you were in the UK. In that situation I’m sure that Stilldragon Europe would be the best way to go because of the incredibly expensive shipping costs for us to ship to the UK. Also Silk’s advice is very good and may be the best way for you to proceed considering that you have already purchased the still.

-

Hey @Silk City Distillers do you think this bill of materials is optimal? column diameter, height, power? I can reduce column to 3″ and have more or less power.. in fact having just 1 x 5kw (rather than 2 x 3kw) element will actually save me a bunch of ££

a) 3kW 230v 1ph ATEX heater – £1710.00 each + VATb) 4kW 230v 1ph ATEX heater – £1790.00 each + VATc) 5kW 230v 1ph ATEX heater – £1900.00 each + VAT

use my 100l kettle (900mm) (already have this)

4″ Bubble section with thermowell (156mm) https://www.stilldragon.eu/en/dash-columns/287-bubble-section-with-thermowell-for-4-inch-dash-sgk.html

4″ column filled with SPP (1500mm – could maybe stretch to 1700mm but wouldn’t know until I am in situ)

4″ Super Dephleg (300m) https://www.stilldragon.eu/en/condensers/30-4-inch-super-dephlegmator.html

4″ to 3″ reducer – into a 180 bend (adds 250mm) then into a 3″ PC (already have this)

-

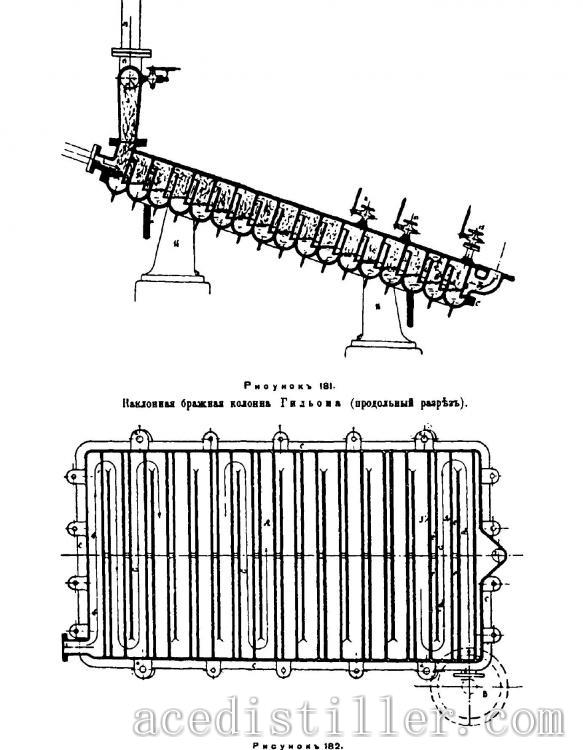

There is a common problem: distillation columns require great heights because they use gravitational temperature separation in height.

Do you want to use 10 plates? This will not give you alcohol above 89-92% … To get high purity alcohol (94-95.5%) you need at least 24, preferably 45-48 plates.

You need to think about using vacuum distillation, it gives the best purity at low temperatures. As for low ceilings, there is a horizontal stripping column solution. It can have a height of only 1-2 meters but about 10-20 steps (plates).

Log in to reply.