-

Extended Length RTD Probes

Posted by jocko on May 3, 2023 at 3:42 pmHello! We are about to commission our new still, and I’ve dusted off my tech skills and written some monitoring software to allow me to set alerts for key temps at various key points in the process.

One place I’ve always monitored closely was the still temp — the liquid itself. The new still (1500L) has an analog thermometer with a 40″ probe. I want an RTD probe of similar length, ideally with a 1/2″ NPT thread at the top.

I’ve been looking but not seen anything beyond 24″. Does anyone know of any quality RTD (3 wire) probes that are extra long. 40″ or even longer ideal.

Also, curious where people m

richard1 replied 1 year, 7 months ago 4 Members · 10 Replies -

10 Replies

-

Curious why other than being basic informative you would want to measure liquid temp. Other vapour parts of the still are way more important.

-

@richard1, I track liquid temp in the pot, vapor temp in the pot, top of onion temp, temp at bottom of dephleg, temp at top of dephleg, temp at top of condenser, temp of distillate, temp of water going into condenser, temp of water leaving dephleg, temp of water tank, etc. I have done this for a while on our smaller still and correleate all of that data with cut points based on the recipe, spirit type, whether its a stripping run, etc. It’s been pretty interesting and provided some insights. Plus, I’m a recovering engineer and it’s basically free information that is constantly being created nearly free to store. It also is really healpful as my little program I wrote will automatically set an alarm a few degrees under the boiling point based on the ABV (per the various ethanol phase diagram data) to ensure that the closed-loop water system was is turned on in advance of the first distillate. I don’t automate anything but it makes it easy to train someone to know what to do, as well as log that it happened (training problem). I log everything so if an alarm went off, someone made a potentially dangerous mistake.

Pour, the still geometry dictates that from where a port is available to just below the condensate returns from the column and gin basket, that the probe be that long to guarantee liquid contact. I was thinking of having our welder create a lower port, but that’s more expensive and intrusive. If I could find a longer probe, it would be fast & easy.

-

@jocko Good to hear that other points are being measured. I have a fully automated LM still and also have numerous measuring points. In my program, all points are monitored / interlocked with the exception of the column’s 2’nd lowest point which I inserted for interest.

-

Love to see! A man of my own heart. I don’t automate anything (although I could, obviously). My goal is to fully understand — over many fermentations & distillations — how small things impact the distillation, what gets put into the barrel/tank, and final product. I track much more than this (and I suspect you do as well)… this is just the distillation piece. I’ve been doing this for many years, and seem to understand each spirit better over time.

-

@richard1, I like the interface you use. Curious what are all the bits you collect. My program does some things and I continue to expand it. I’d like to make it more useful to others. Right now, I basically use it to keep an eye on things. Alarms for any point monitored, which has proven very useful for when something unexpected happens. I also track every collection point every 60 seconds. There’s a separate program that just plots the temps over time on a chart which is a good visual to see if something is trending in an unexpected direction. I can glance at that and see instantly when something may be needing adjustment.

I’d like to do more. I want to make it somewhat mistake-resilient so that someone can be trained to monitor things and what to do when key events happen.

What do you monitor? What do you store? What do you do with all your data? Please share as much as you are willing.

-

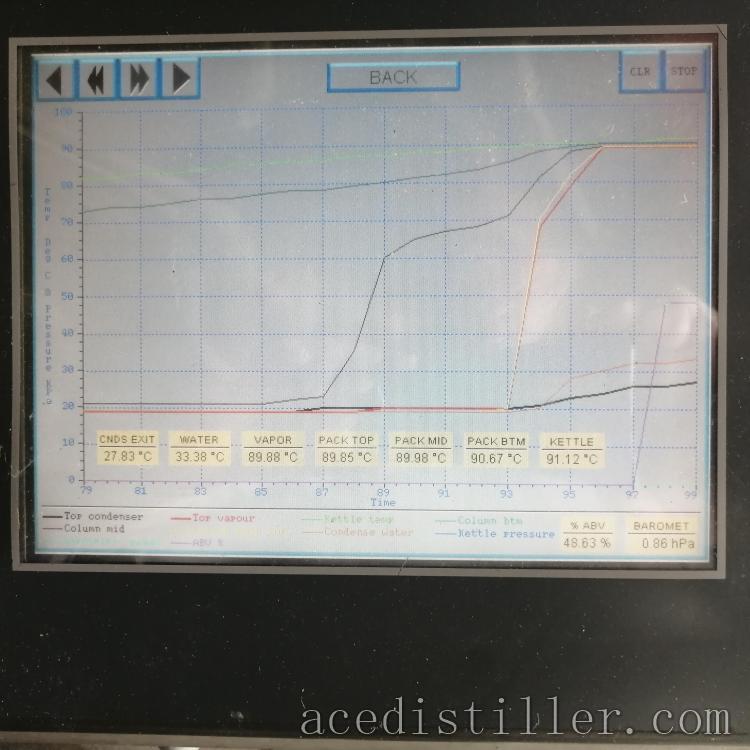

Basically with the exception of the 2nd lowest column temp probe I monitor everything. Though I could, I do not store the data for future use, however I do have it being plotted on the HMI trend graph. …. Excuse the decimal point error in atmospheric pressure.

An example of this is shown below

-

Can you discuss more the design realities of your kettle? What is it’s dimensions, when charged where is liquid coming up to, where does probe insert and how far does it have to travel to be submerged? Will there ever be runs where it will become completely “unsubmerged”? Do you have elements or jackets? Do you have a level indicator like our friend from SA shows on his still? Would it be possible to come up from bottom within drain or would jacket/elements interfere/be in way?

-

@jocko Unfortunately with my PLC, I can not load and read Excel Lookup tables where I also have my pressure and temperature tables for % ABV. So within certain ranges, I use a formula linked with calibration correction. This is then quite accurate for % ABV values. As always, is for information only and must be confirmed with other means.

Log in to reply.