Home › Forums › Equipment › Considering a shift to continuous operation: Evaluating potential modifications to the distillation column

-

Considering a shift to continuous operation: Evaluating potential modifications to the distillation column

Posted by silverswede on September 20, 2023 at 1:05 pmHave anyone modified “hot rodded’ their hybrid type still with existing column(s) so it can be used as a continuous stripping still.

bolverk replied 1 year, 2 months ago 6 Members · 24 Replies -

24 Replies

-

There’s a really great older thread on SD where one guy modded his and a few built from scratch. Might be able to get some ideas from it.

https://www.stilldragon.org/discussion/1923/m-yet-another-continuous-stripper-idea/p1

-

I am following this with interest.

Several years ago I built a continuous stripping still that is very energy efficient and doesn’t require any cooling water. The output from this is then pot distilled to do the cuts.

I am this week installing a 6 plate bubble cap column that should do the cuts continuously. The column is slightly modified “hot rodded” so I can draw off selected plates. There is a big energy saving because the vapour from the stripping column is not condensed and re-boiled.

A regular pot with column that is run as a fill then empty batch production won’t give consistent products off each plate.

-

Pete, I hope you can post some pics of this evolution of your column system.

-

I second this!

I’m working on a 4″ continous stripping column but I’m only about halfway through the build.

-

It is probably obvious to those who are working with continuous columns, but just a heads-up to those who are thinking of going that way – the usual way of taking the vapor from the stripping column across to the rectifier is to install the take-off slightly below the top of the stripper. With a continuous stripper there can be some really bad smelling stuff accumulated at the top of the stripper and you don’t want to take that over into the rectifier. You need a small sacrificial bleed stream from the condensed heads on the stripper, or by adjusting the condenser temperature to allow the smellies to be vented to atmosphere.

It is also general practice to have a reboiler on the rectifier but it would be interesting to see how it would work if the bottoms of the rectifier are taken back to the stripper for reboiling – much like what is done in a craft batch plant. If the rectifier bottoms are taken back to the stripper make sure there is a U-seal in the line to prevent vapor flowing up this line into the base of the rectifier when there should only be liquid flowing from the rectifier back to the stripper.

-

So look into a doubler off an ABC system, thats a continuous pot still. Work best fed off wines though so you’d still need a stripping function to your system IDK if you can realistically achieve same results with grain in (heating elements).

Have modified a few columns feel free to chirp at me. Joey (Joseph, not Joey) Dehner doesn’t come around much anymore but if anyone could figure it out for you he could.

Obviously I am assuming you’ve looked at an armagnac still? its literally doing what you ask, although it isn’t at a start place of the hybrid column you have on site, it is exactly what you want to do functionally.

Cheers,

NBM

-

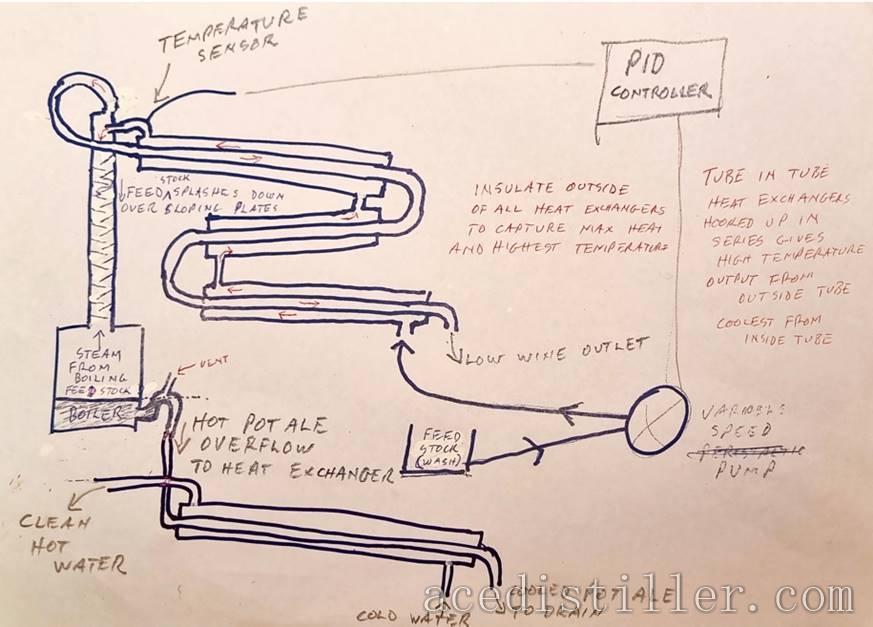

Apologies to those who have been waiting for this image that I said I would upload over a year ago.

Attached diagram of my continuous stripper. Not easy to understand from photos.

The boiler is heated with a waste fryer oil burner, once it is running the heat is turned way down because of heat recovered from condenser.

No cooling water required.

This column now dismantled and will feed a 6 plate bubble cap, 6 inch rectifier.

Preheating of the wash for the 2 column setup will be mostly from the boiler outflow. EDIT for clarity, boiler outflow is “bottoms”

-

I’m basically doing a shorter version of what this guy has here

https://youtu.be/hizh9hNVNzo?si=8A8Ll5p3s79z8jKj

-

IDK if its just me but the photo won’t load on your post

-

This is an awesome set up. Obviously some efficiencies to be gained here but very little (just close the lids on those coolers!)

Are you running a set up like this for neutrals?

-

I’m only about halfway though my build… But I’d be using it as a stripper for rum.

Yeah it’s about as efficient as I’ve seen. If his numbers are accurate (I’m not doubting him) he’s running 6000w and stripping 3-3.2lpm through a 4″, that’s huge!

-

It’s quite impressive for sure unfortunately it’s tough to scale electric to mass production sizes so execution is limited but where it is applicable it is quite impressive. The watt and yield leave out the water consumption. It’s pretty impressive to not have coolant water consumption. Not unheard of, but always impressive when it pops up.

Have you looked into any dewatering shit for stillage? Some of those units blow my fucking mind!

Just my .02!

Slick

-

Not sure about his system but I’ve seen similarly sized used around 200ml per minute. I know there’s a way to figure it out, I just don’t know how to do that.

I haven’t until now lol, that’s another whole other rabbit hole to go down…

-

SlickFloss couldn’t download my photo, did it download for others?

-

Can you see my hand drawn sketch of my continuous or you referring to another photo?

It shows in my post but I will probably need to re-format it for others

-

Trying again to post a sketch of my continuous stripping still

-

So you’re not recapturing the heat from your bottoms? Are you doing anything with that heated water?

-

On a smaller version of the continuous I found the extra heat from the bottoms didn’t contribute much to efficiency, and caused quite a delay in stabilising the system.

I have a series of large hot water cylinders that the hot water feeds through, the final one is a heat pump type (for efficiency) There is a thermostat and pump on the bottoms heat exchanger. When the water gets to 80 deg C the water is pumped into the top of the final cylinder which means the heat pump rarely needs to work. Colder water, but still quite hot, is pushed out the bottom of this cylinder into the top of the next one etc. The hot water circulates through the cylinders heating them all. When still is running there is no need for the heat pump to boost the temperature. Plenty of almost free hot water for cleaning, mashing etc.

-

Fair, as long as your wash is getting up to column temps before it enters (and I’m sure yours is with 3 HX) the bottoms recovery isn’t necessary.

Very cool, At least you’re still recovering it and putting that power (hot water) to good use somewhere else.

Everything I’ve read about a system that reboilers the beer for steam has foam issues. Have you experienced this as well?

I’d love you see a video of yours in action… if you could post it.

Log in to reply.